WAMGROUP®

Shared Values, Trusted Choice.

Precision feeding for powders and granules with Trouble-free cleaning

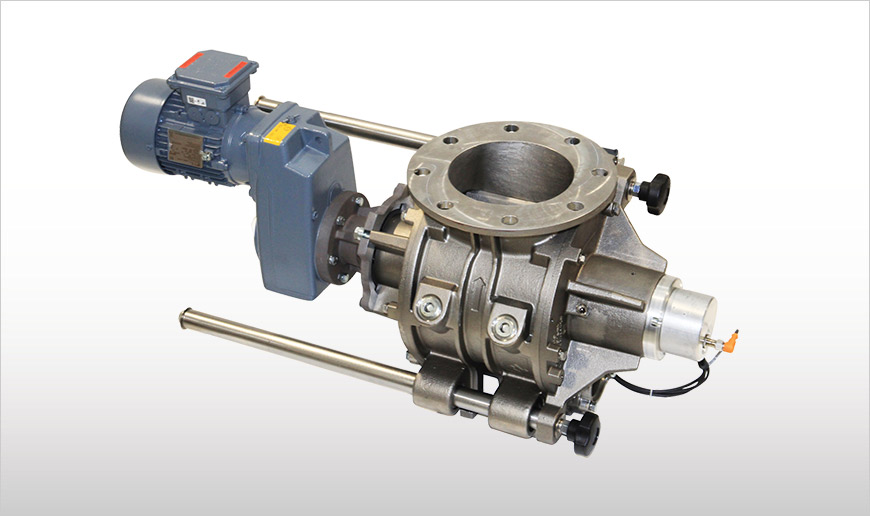

SlideOut Rotary Valves are engineered with a continuously revolving rotor featuring two compartments, both of which are filled with material simultaneously via the top inlet.

The valves come in two distinct versions: REC and RES.

The REC Drop-through SlideOut Rotary Valve is equipped with a circular inlet and outlet. The material fed by the rotor falls by gravity through the lower outlet into a container or onto a downstream conveying system for further processing.

With the RES Blow-through SlideOut Rotary Valve also featuring a circular inlet flange and an outlet pipe connection on the bottom on both sides, after less than half a rotor revolution, the material is discharged and channelled into an air flow within a pneumatic conveying line.

Fill out the form to receive more information